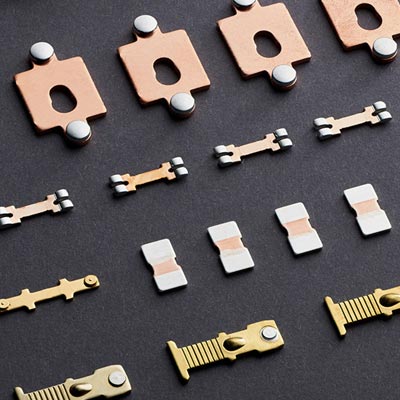

Contact and stamped parts

Thanks to its expertise in the manufacture and processing of contact materials SAXONIA can offer you a wide range of contact parts, contact rivets and pads, contact profiles and precision stamped and bent parts – manufactured individually according to your wishes. With decades of experience in the processing of precious metals and their alloys, our contact and stamped parts are used in a variety of sectors – such as in switching and control engineering, electronics and electrical engineering, telecommunications and safety technology as well as in the automotive industry. Upon request, we also manufacture complete assemblies to your specifications, galvanised, mounted or plastic coated. We can also assist you from the design of the parts via the selection of the materials, the production and testing of the parts.

Contact parts, contact rivets and pads

SAXONIA provides you with a wide range of contact parts and high-class contact rivet and pads for switching devices and relays – individually according to customer drawings.

- Individual contact rivets in solid form or as bimetallic rivets

- Contacts as welded, riveted or soldered complete solutions

- Contacts as a stamped and bent part of a contact profile, pre-fitted with contact material

- Contact pad as welded contact, rivet, platelet or galvanised surface

- Welding contact by resistance or laser welding on the solid or pre-stamped carrier material

Our contact parts are available in different finishes:

- with / without contacts, threading and inserting screws

- galvanised with tin, silver, gold or other metals, for improving conductivity or corrosion protection

Our contact parts are available in the following forms:

- in bulk

- stamped strip on reel

| Carrier materials | Thickness | Width |

|---|---|---|

| Copper and copper alloys (E-Cu / CuSn / CuZn / CuAg / CuBe) |

0.5 … 4.0 mm | 4.0 … 25.0 mm |

| Contact materials | Thickness | Width |

|---|---|---|

| Ag 99.97 | 0.2 … 4.0 mm | 0.65 … 20.0 mm |

| AgNi | 0.2 … 4.0 mm | 0.65 … 20.0 mm |

| AgCu | 0.2 … 4.0 mm | 0.65 … 20.0 mm |

| AgSnO2 | 0.2 … 4.0 mm | 0.65 … 20.0 mm |

| AgSnO2In2O3 | 0.2 … 4.0 mm | 0.65 … 20.0 mm |

Other combinations and dimensions are available upon request.

Contact profiles

Seam-welded contact profiles from SAXONIA are produced in up to 4 layers on a double-head welding installation as inlays or toplays. They are used as semi-finished products in the processing industry, or as an intermediate product for our own contact-part production.

| Carrier materials | Thickness | Width |

|---|---|---|

| Copper and copper alloys (E-Cu / CuSn / CuZn / CuAg / CuBe) |

0.5 … 2.0 mm | 12.0 … 60.0 mm |

| Contact materials | Thickness | Width |

|---|---|---|

| Ag 99.97 | 0.5 … 3.0 mm | 0.65 … 6.0 mm |

| AgNi | 0.5 … 3.0 mm | 0.65 … 6.0 mm |

| AgCu | 0.5 … 3.0 mm | 0.65 … 6.0 mm |

| AgSnO2 | 0.5 … 3.0 mm | 0.65 … 6.0 mm |

| AgSnO2In2O3 | 0.5 … 3.0 mm | 0.65 … 6.0 mm |

Other combinations and dimensions are available upon request.

Stamped and bent parts

Stamped and bent parts from SAXONIA are produced on our high-performance stamping machines to individual customer requirements.

- Coated or galvanised

- Threaded or screwed

- Galvanised with tin, silver, gold or other precious metals to ensure conductivity and corrosion protection

We supply our stamped and bent parts:

- in bulk

- stamped strip on reel

| Materials | Thickness | Width |

|---|---|---|

| Copper and copper alloys (E-Cu / CuSn / CuZn) | 0.15 … 4.0 mm | 0.65 … 60.0 mm |

| Nickel and nickel alloys | 0.15 … 4.0 mm | 0.65 … 60.0 mm |

| Thermo bimetals | 0.15 … 4.0 mm | 0.65 … 60.0 mm |

| Steel, plated steel | 0.15 … 4.0 mm | 0.65 … 60.0 mm |

Other materials and dimensions are available upon request.

Tool manufacture for contact and stamped parts

SAXONIA not only makes finished contacts, stamped and bent parts, but also designs and manufactures all of the tools needed for in-house production. All the facilities for various production processes are available, such as EDM and wire cutting, surface grinding, milling and turning. Of course, our tools are regularly checked before and after use, and maintained so that trouble-free application is guaranteed in our production at any time.

Quality

At SAXONIA quality takes top priority – both in terms of precious metal purity and in production and processing. By diverse testing methods and modern laboratory equipment we ensure every time that all the products we manufacture always meet our high quality standards.

Extensive facilities:

- Chemical laboratory

- Materials laboratory

- Metallography laboratory

- Test laboratory

Extensive testing methods:

- layer thickness

- microstructures

- surface roughness

- geometry and spring forces

- tensile and compression tests

- shearing force

- SPC check

Individual consulting

We advise you, for example, in selecting materials, coatings and structures – and support you on request during the process of developing your future products. Simply contact us at any time.