Semi-finished products

SAXONIA offers a wide range of semi-finished products. Our product portfolio ranges from individual melting products, tubes, rods, sheets and wires to anodes, targets, precision strips, milled and turned parts. Our high-quality semi-finished products are used as technical materials in many industrial sectors, or represent top-quality pre-materials for jewellery or investment goods. Depending on product, quality and customer requirements, for producing our semi-finished products we use both melting metallurgical processes – such as vacuum casting or continuous casting – and sintered materials.

Applications

Melting products and plates

Our melting products are manufactured according to your wishes in different sizes and grades. Both as full semi-finished products or as a high-quality pre-material for the production of semi-finished and end-user products.

| melting products, plates | Characteristics |

|---|---|

| Application | Pre-material for many precious metal applications, semi-finished products, turned parts etc. |

| Alloy | Melted metallurgical materials |

| Moulds | round, flat, freeform |

| Dimensions | Standard casting size: 23 x 300 x 370 mm |

| Casting | Vacuum casting, continuous casting |

| Quality | annealed / not annealed, rolled, milled, sawn, turned, etc. |

Targets and evaporation materials

We produce targets and vacuum evaporation materials from precious metals in thin-film technology for various cleanroom and vacuum applications: these include optical data storage, electronics, glass coating (low-E), photovoltaic foil coating and mirror production – SAXONIA supplies you with high-quality high-tech products.

Our targets can also be used as consumable material for sputtering in magnetrons. Here the coated object is given special wave-dependent (for example, heat-reflective or translucent) properties.

| Targets, evaporation materials | Characteristics |

|---|---|

| Application | Thin-film technology for cleanroom and vacuum applications, in optical data storage, electronics, glass coating (low-E), photovoltaics, foil coating and mirror production. |

| Alloy | Melted metallurgical materials (in particular high-purity materials made of Ag, AgPd, AgAu) |

| Moulds | As per drawing (flat, round, slug, clippings etc.) |

| Dimensions | Segmented large targets up to 4m, thickness up to 2 inches (about 50 mm), panel length to 1.5 m, round targets etc. |

| Casting | Various grades according to customer specifications |

| Quality | Surface milled, tolerances according to drawing |

Anodes, dogbones and clippings

With anodes, dogbones and clippings from SAXONIA you receive high-purity precious metal products for eletroplating surface treatment, refinement and implementation of specific technical and functional characteristics – always in the best quality and in a wide range of alloys with a very high degree of purity.

| Anodes, dogbones, clippings | Characteristics |

|---|---|

| Application | Electroplating (electrochemical separation of metallic deposits), surface finishing technology |

| Alloy | Ag from 99.9 to 99.99% |

| Moulds | flat, round, possibly with hole or punched (as per drawing) |

| Dimensions | Standard anodes: 3 – 15 (thickness) x ≤370 (width) x ≤1000 mm (length) Standard clipping: Ø 11 x 10 mm Dogbones: length up to 1000 mm; 5 Standard dimensions |

| Casting | Vacuum casting, continuous casting |

| Quality | Anodes: soft annealed Dogbones: rolled or drawn |

Sheets and discs

Our sheets and discs are ideal pre-material for various decorative products for consumers, such as cutlery or silverware. Of course they are also ideal for use in functional applications, such as in the chemical industry.

| Sheets, discs | Characteristics |

|---|---|

| Application | Chemical industry, electrical equipment, gaskets, medical products and jewellery making |

| Alloy | Melted metallurgical materials |

| Moulds | flat, round |

| Dimensions | Sheet: ≥0.2 x ≤500 x ≤1000 mm Disc: Ø 600 mm or special forms |

| Casting | Vacuum casting, continuous casting |

| Quality | Hardness: hard rolled or annealed Surface: rolled, brushed or polished, foiled for surface protection |

Coin strips and blanks

Coin strips and blanks from SAXONIA are high-quality, semi-finished products from different precious metals as pre-material for individual investment products, coins and medals made to customer specifications.

| Coin strips and blanks | Characteristics |

|---|---|

| Application | Jewellery, coins, medals, badges, other investment products |

| Alloy | Melted metallurgical materials |

| Moulds | flat, round |

| Dimensions | Standard width: ≤ 120 mm, standard length: ≤600mm |

| Casting | Vacuum casting, continuous casting |

| Quality | Specifications: tolerances (thickness / width), hardness, surface |

Round wires and profile wires

From primary material to the finest wire – SAXONIA offers a wide range of precious metal wires for different technical applications.

| Round wires and profile wires | Characteristics |

|---|---|

| Application | Electrical engineering (switches, contacts, motors, fuses, sensors), medical products and jewellery (e.g. chains) |

| Alloy | Melted metallurgical materials and sintered materials |

| Moulds | Round wire, profiles on request (square, rectangular, semicircular, hexagonal etc.) |

| Dimensions | Standard diameter: 0.1 to 6 mm (<0.1 mm fine wire and> 6 mm primary material on request) |

| Casting | Vacuum casting, continuous casting, pressed sintered materials |

| Quality | Extrudion press wire (higher quality) and continuously casted wire Specifications: tolerance diameter, resistivity, conductivity, hardness, elongation, tensile strength, surface finish Wire drawing peeled ≤6mm |

Rods and tubes

Our rods and tubes are excellent pre-material for functional and decorative end products.

| Rods and tubes | Characteristics |

|---|---|

| Application | Chemical industry, electrical engineering, medical equipment and jewellery |

| Alloy | Melted metallurgical materials |

| Moulds | Round wire, profiles on request (square, rectangular, semicircular, hexagonal etc.) |

| Dimensions | Standard length: 1m – 2.4m Standard thickness: 1 mm – 60 mm |

| Casting | Vacuum casting, continuous casting |

| Quality | seamlessly extruded and welded |

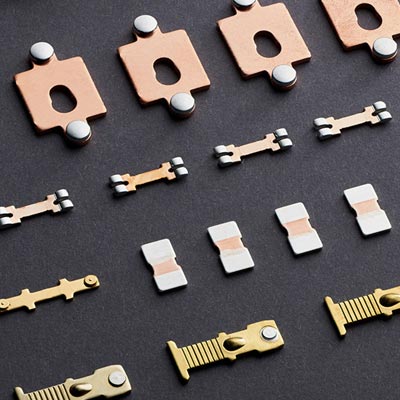

Precision strips, profiles, fusible elements

As a longtime partner to the electrical industry and reputable fuse manufacturers, our high-tech products meet all the standards required, for example, in low voltage and high voltage applications.

| Precision strips, profiles, fusible elements | Characteristics |

|---|---|

| Application | Jewellery, electrical (contacts, fuses) and medical equipment |

| Alloy | Ag, Cu silver plated or tinned |

| Moulds | Strip, flat wire, profiles to drawing |

| Dimensions | Thickness: ≥ 0.03 mm, width of foil: ≤ 100 mm, width of strip: ≤ 350 mm |

| Casting | Vacuum casting, continuous casting, sintered materials |

| Quality | Specifications: tolerances (thickness / width), resistivity, conductivity, hardness, elongation, tensile strength, surface |

Milled parts and turned parts

To your specifications SAXONIA provides you with individual, precision machined and milled parts in CNC-controlled production for decorative and functional applications.

| Milled parts, turned parts | Characteristics |

|---|---|

| Application | Jewellery and technology (machines / equipment) |

| Alloy | Melted metallurgical materials |

| Moulds | according to drawing |

| Dimensions | Thickness: 5 mm – 100 mm, length: to 600 mm |

| Casting | Vacuum casting, continuous casting |

| Quality | Roughness: Rz ≤ 1 µm, tolerances according to drawing |

Overview of materials

| Materials | Precious metal content in mass% | other elements | Melting temp. / range in ° C | Density in g / cm³ |

|---|---|---|---|---|

| Silver | ||||

| Ag 99.999 % | 100.00 | – | 962 | 10.5 |

| Ag 9999 | 99.99 … 99.995 | – | 962 | 10.5 |

| Ag 9997 | 99.97 | Cu | 962 | 10.5 |

| Ag 999 | 99.90 | Cu | 962 | 10.5 |

| AgNi0.15% | 99.85 | Ni | 960 | 10.5 |

| AgCu2Ni0.15 | 97.85 | Cu, Ni | 940 | 10.4 |

| AgCu3Ni0.15 | 96.85 | Cu, Ni | 910 … 930 | 10.4 |

| AgCu (1 to 20% Cu) | 99.00 … 80.00 | Cu | 779 … 950 | 10.1 … 10.4 |

| AgCu28 | 72.00 | Cu | 779 | 10.0 |

| AgCu50 | 50.00 | Cu | 779 … 865 | 9.7 |

| AgCu70 | 30.00 | Cu | 779 … 945 | 9.35 |

| AgCu80 | 20.00 | Cu | 779 … 990 | 9.2 |

| CuAg (1 to 10%) | 10.00 … 1.00 | Cu | 779 … 1080 | 8.9 … 9.1 |

| Ag 935 | 93.50 | Cu | 835 … 900 | 10.4 |

| Ag 925 | 92.50 | Cu | 810 … 890 | 10.35 |

| Ag 900 | 90.00 | Cu | 779 … 870 | 10.3 |

| Ag 835 | 83.50 | Cu | 779 … 830 | 10.2 |

| Ag 800 | 80.00 | Cu | 779 … 810 | 10.15 |

| Ag 500 | 50.00 | Cu | 779 … 865 | 9.7 |

| Ag 333 | 33.30 | Cu | 779 … 930 | 9.4 |

| AgNi10 | 90.00 | Ni | (961) | 10.3 |

| AgNi15 | 85.00 | Ni | (961) | 10.2 |

| AgNi20 | 80.00 | Ni | (961) | 10.1 |

| AgNi40 | 60.00 | Ni | (961) | 9.7 |

| Gold | ||||

| Au 99.999 % | 100.00 | – | 1064 | 19.3 |

| Au 9999 | 99.99 … 99.995 | – | 1064 | 19.3 |

| Au 999 | 99.90 | Cu | 1064 | 19.3 |

| AgAu1 | 1.00 | Ag | 963 | 10.5 |

| Platinum | ||||

| Pt 99.99 % | 100,00 | – | 1772 | 21.45 |

| Pt 999 | 99.90 | 1772 | 21.45 | |

| PtRh5 | 95.00 | Rh | 1820 | 20.6 |

| PtRh10 | 90.00 | Rh | 1840 … 1850 | 20.0 |

| PtRh20 | 80.00 | Rh | 1890 … 1910 | 18.7 |

| PtAu (5 to 30 %) | 95.00 … 70.00 | Au | 1675 … 1745 | 21.3 … 20.8 |

| PtIr (1 to 10 %) | 99.00 … 90.00 | Ir | 1780 … 1800 | 21.5 … 21.6 |

| Palladium | ||||

| Pd 99.99 % | 100.00 | – | 1555 | 12.0 |

| Pd 999 | 99.90 | 1555 | 12.0 | |

| AgPd10 | 10.00 | Ag | 1030 … 1065 | 10.6 |

| AgPd20 | 20.00 | Ag | 1105 … 1135 | 10.8 |

| Copper | ||||

| Cu 99.99 % | 99.99 | – | 1085 | 8.9 |

| Cu galv. 0.6 – 3%Ag | 99.4 … 97.00 | Ag | 1085 | 9.0 |

| Indium | ||||

| In 99.9 % | 99.90 | – | 157 | 7.31 |

Quality

At SAXONIA quality takes top priority – both in terms of precious metal purity and in production and processing. By diverse testing methods and modern laboratory equipment we ensure at all times that all the products we manufacture always meet our high quality standards.

Extensive facilities:

- Chemical laboratory

- Materials laboratory

- Metallography laboratory

- Test laboratory

Extensive testing methods:

- layer thickness

- microstructures

- surface roughness

- geometry and spring forces

- tensile and compression tests

- shearing force

- SPC check

Individual consulting

We will be happy to advise you, for example on the choice of materials and their properties, coatings and structures – and on request support you during the development process for your future products. Simply contact us at any time.